What force can a liteECO® Actuator apply statically and dynamically?

Depending on the actuator configuration, forces up to 750 N can be applied statically (75 kg vertical load). The nominal force for dynamic processes is 33 % (poor thermal connection) to 50 % (good thermal connection) of the maximum force. The maximum load capacity must not be exceeded for dynamic loads.

Please contact us to calculate your individual movement profiles.

With which motion controller can the liteECO® actuators be operated?

LiteECO® actuators are proven with controllers of the following manufacturers:

Contact us for questions about control via different bus systems. We will be happy to assist you in selecting the appropriate control system and check compatibility with your system components.

What are the benefits of switching to an all-electric infrastructure?

The use of electromechanical actuators instead of pneumatic systems leads to a significantly simplification of the system infrastructure and an associated faster commissioning. The reduced component use leads to a more advantageous ecological footprint of the systems.

Whereas the SMELA liteECO® actuators only require a motion controller, a pneumatic cylinder requires a complete compressed air infrastructure consisting of a compressor, pressure vessels, leaky hoses, valves, valve actuators as well as a power supply.

The maintenance effort of these compressed air systems, with continuous lubrication and cleaning as well as filter changes and leakage repairs, represents a non-negligible personnel expense with additional material costs.

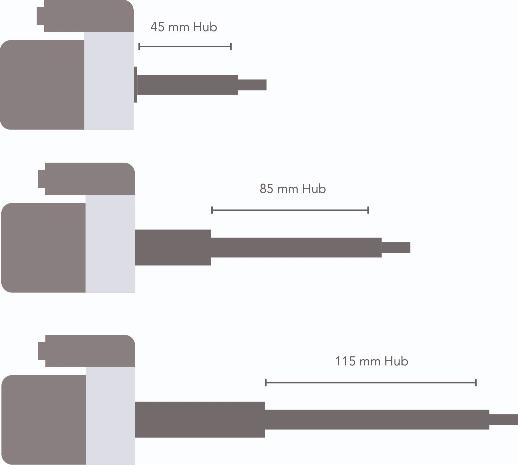

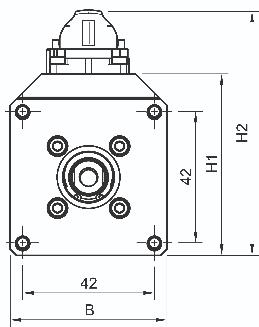

The LE-BASE.50 size has an external flange dimension (A) of 50 x 50 mm with a mounting hole spacing of 42 x 42 mm.

As the liteECO® series does not exceed the installation length with the same stroke of the pneumatic cylinders, the actuators can be used without any further adaptation effort. Provided that the force and dynamics meet the requirements.

Can the motion profiles be parameterized?

This allows digital or analog inputs to be easily ealuated and used in programmed state machines in addition to setpoint specification via a bus system (e.g. CAN, EtherCAT, Profinet oder Profibus).

For small systems/automats without higher-level control or for quick commissioning by mechanics without programming knowledge, this can be useful and helpful.

The accompanying video shows a simple switch function for picking and logistics systems. The desired positions can easily be programmed by hand, without PC or bus connection. Via digital inputs (pushbuttons), binary signals or bus systems the control in the machine can be done.

Damit schont unser nachhaltiges Design nicht nur wertvolle Ressourcen, sondern reduziert auch Industrieschrott.

Contact us for further informations, the individual life cycle determination or the processing of a refurbishment: service@smela.com

Where are liteECO® actuators used?

The liteECO® linear actuators are ideal for applications that require short linear movements: e.g. in production lines, machine tools or packaging systems. For simple and complex movements: for fixing, adjusting, locking or traversing any motion profiles.

Do you have any questions?

It would be a pleasure for our experts to answer your questions.