The new BASE series

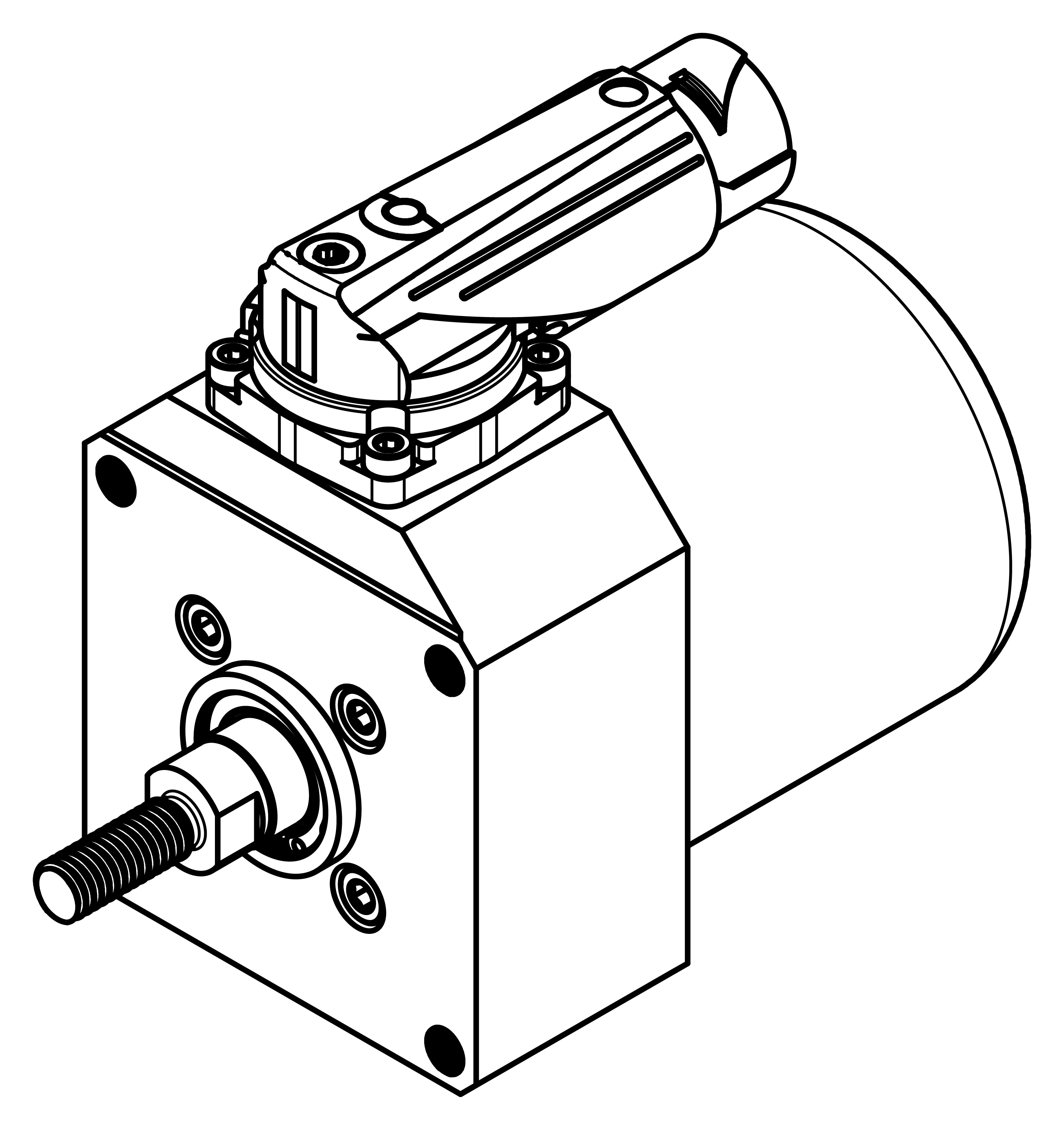

The LE-BASE actuators integrate many of the advantages of electric actuators and supplement them with essential features for demanding industrial requirements. In addition to sealing to protection class IP65, rotatable circular connectors of size M15 with a self-locking quick-release system have been integrated. The maximum stroke is scalable in steps of 45, 85 and 115 millimetres, whereby any positioning within the maximum stroke is possible without restriction. A centring collar has been provided on the flange for mounting and alignment in customer applications. Optional swivelling and adapter flanges, which can be mounted on both the front and rear of the actuator, ensure greater flexibility.

The BASE series does not have an integrated drive controller and is therefore independent in the use of preceding controls. The freedom to use different controller manufacturers thus enables integration into various bus systems and leaves all control options open to the plant manufacturers and operators. Compatible motion controllers can be found hier

The liteECO® Concept:

The SMELA liteECO® series is the most compact electromechanical alternative to pneumatic short-stroke cylinders thanks to its patented arrangement of motor and mechanics. This makes them ideal for the many linear movements required in production lines, machine tools or packaging systems.

A servomotor A servomotor including positioning sensors enables the movement of simple to complex profiles: for fixing, adjusting, locking and travelling any movement processes. The highly efficient motor saves up to 90 % energy compared to pneumatic systems. Together with the smart arrangement of the mechanics in the motor, the actuator saves up to 80 % installation space compared to existing electrical solutions. The liteECO® series also offers the option of simple refurbishment. Replacing a worn mechanism is extremely simple and helps the actuators to achieve several life cycles: sustainable, cost- and resource-saving.

SPACE-SAVING

Up to 80 % installation space savings compared to conventional electrical alternatives

ENERGY-SAVING

Up to 75 % energy savings compared to pneumatic systems

INDEPENDENT

Can be used with any motion controllers and bus systems

SINGLE CABLE SOLUTION

Hybrid connection via rotatable circular connector with quick release system

SEALED

to IP65* in various material combinations (on request)

INTEGRATED SENSORS

High-resolution encoder system with various interfaces and resolutions

Product configuration

The product number can be used to configure the mechanics, the stroke and the sensors.

Other configurations on request:

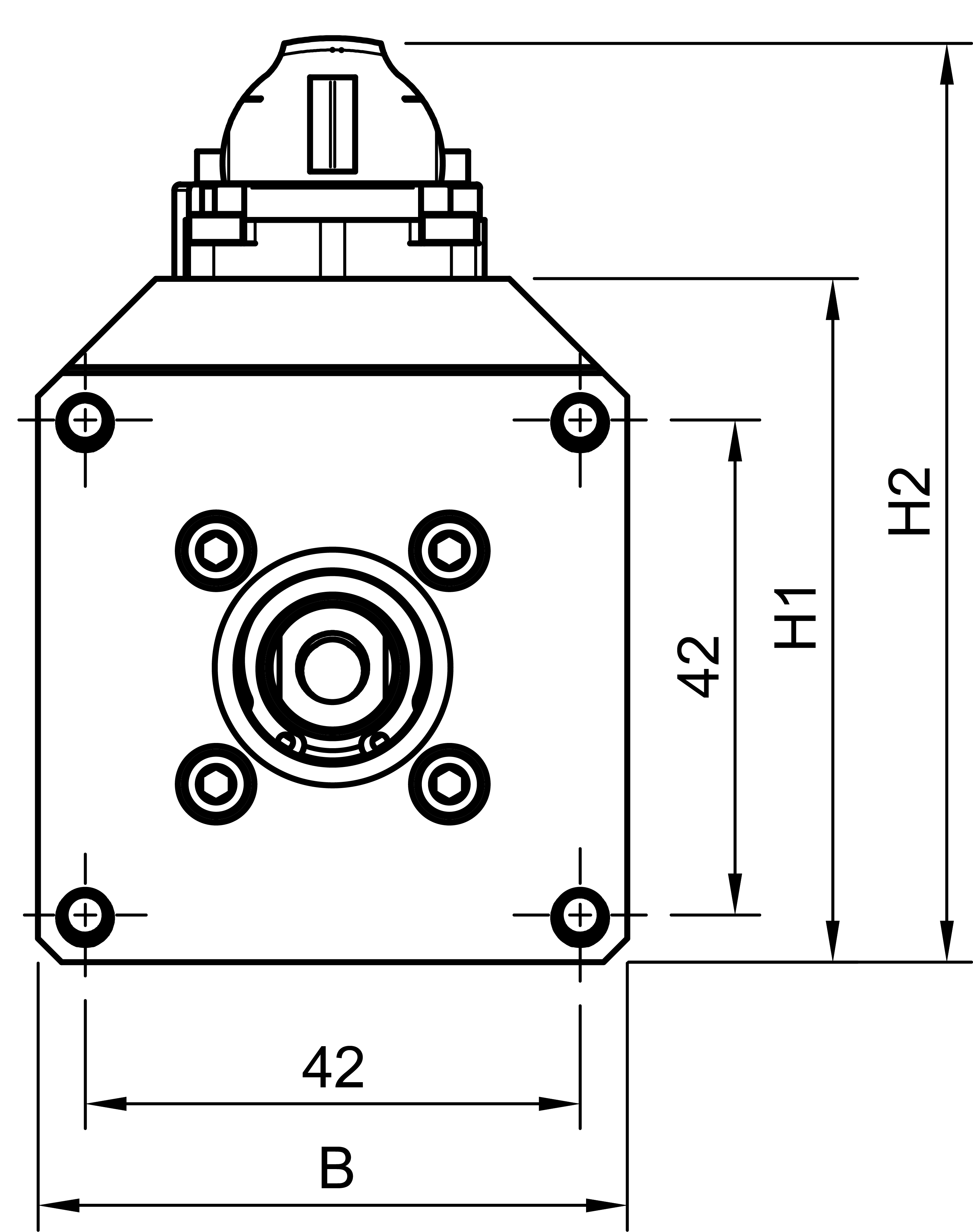

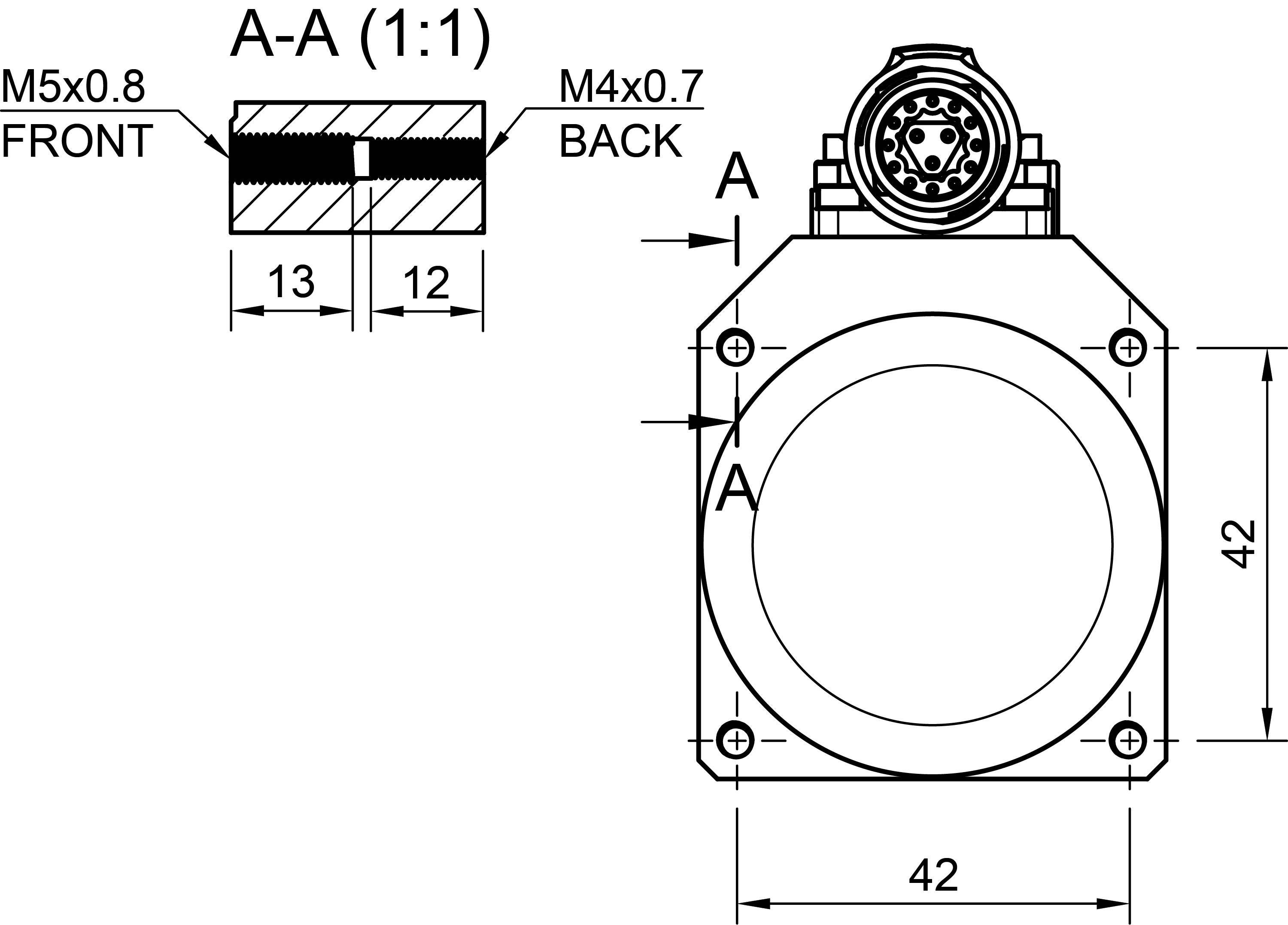

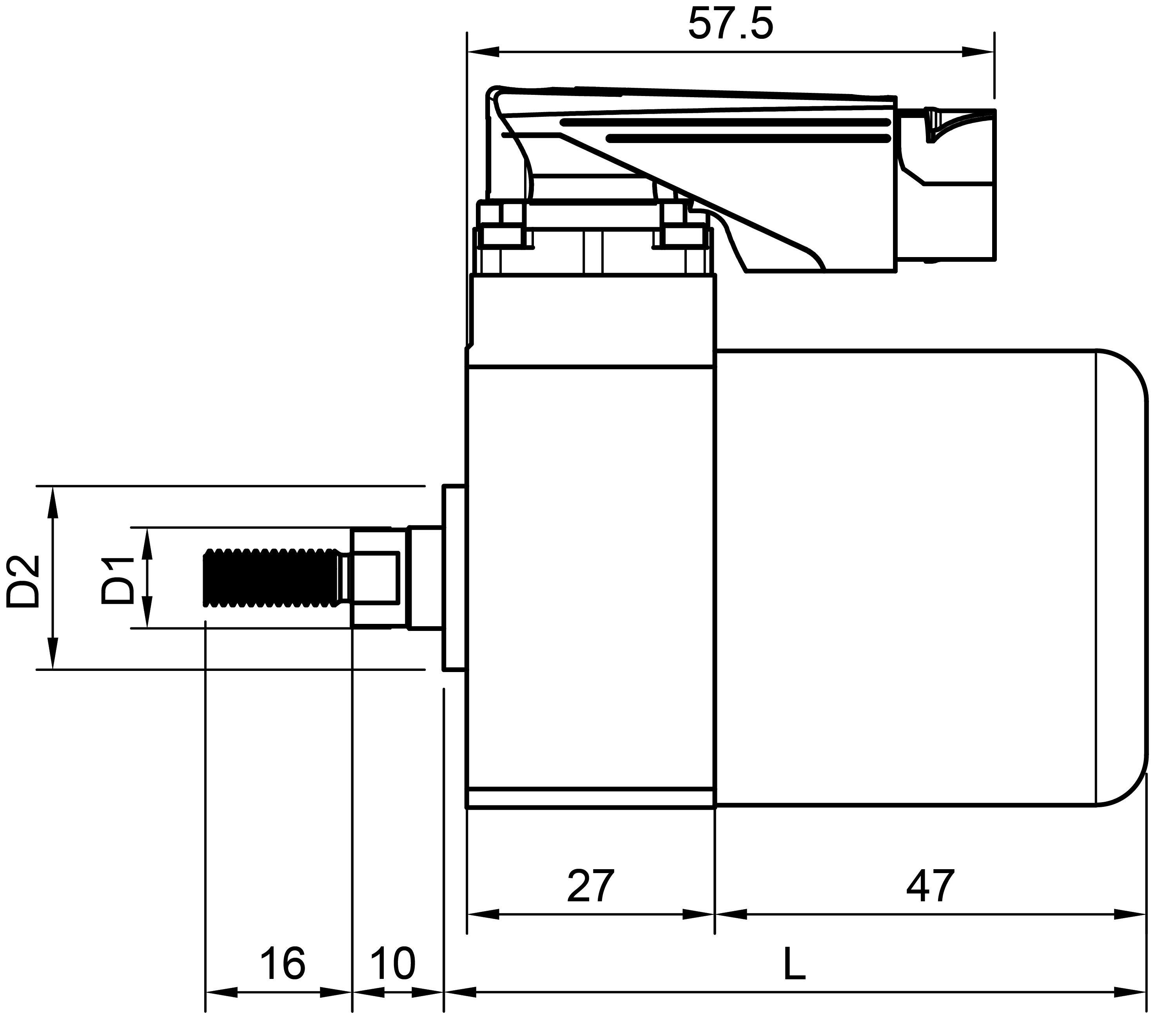

| Dimensions depending on stroke length | 045 | 085 | 115 |

| Stroke S [mm] | 45 | 85 | 115 |

| Length L [mm] | 78 | 118 | 148 |

| Wide B [mm] |

50 | ||

| Height H1 [mm] | 58 | ||

| Height H2 [mm] | 78 | ||

| Centring collar D2 [mm] | Ø 20 x 2,5 | ||

| Diameter plunger D1 [mm] | Ø 11 | ||

|

Thread on the plunger |

M6x16 (external thread) | ||

| Width across flats for fixing the plunger [mm] | 9 | ||

| Weight approx. [g] |

540 | 590 | 640 |

| My, Mz (Lateral forces on the plunger) | < 1 | ||

|

Coupling / bolting to the flange

Mounting options

(1) from the front into the flange

(2) from behind through flange

(3) Accessories (in the back of the flange)

Tightenning torque

(strength class 8.8)

M3 [Nm]

M4 [Nm]

M5 [Nm]

|

42 x 42 4 x M5 Internal thread x Depth 13 mm 4 x M3 (as through hole) 4 x M4 Internal thread x Depth 12 mm 1,3 3,0 6,0 |

||

| Hybrid connection (power & signal) |

M15 Intercontec Itec 915, 15-pole, male angled (rotatable) |

||

|

Degree of protection |

IP65* | ||

|

Materials (of the external components)

Plunger

Flange

Cover

Wiper ring

|

|

||

| Lead screw configuration | Limit loadcapacity [N] |

Peak force [N], Peak current [A] |

Nom. force [N], Nom. current [A] |

Max. speed [mm/s] | Max. accel. [m/s²] | Positioning time [ms] |

| High helix (Backlash approx. ±0,1) | ||||||

| S100 |

300 | 300 N / 12 A |

125 N / 5 A |

500 |

25 | 120 |

| S150 | 300 | 200 N / 12 A |

83 N / 5 A |

750 | 37,5 | 85 |

| S240 | 260 | 125 N / 12 A |

52 N / 5 A |

1.200 | 60 | 65 |

| Trapezoidal thread (Backlash approx. ±0,1) |

||||||

| T020 | 750 | 750 N / 6 A |

625 N / 5 A |

50 | 2,5 | 900 |

| T040 | 750 | 750 N / 12 A |

313 N / 5 A |

100 | 5 | 450 |

| Unit | Value |

|

|

General |

||

| Nominal voltage* | V | 24 to 48 |

| Operating temperature |

°C | +5 to +40 |

| Internal temperature limit |

°C | +90 |

| Motor feedback Measurement system Interface Resolution (increments | quadcounts) |

|

Optical (rotative, singleturn) Incremental, Hall, SSI*, BiSS* 1.024 | 4.096 higher resolutions on request |

|

Motor parameters |

||

| Max. permissible speed (equal to no-load speed at 24 V) |

min-1 |

3.025 |

| Max. acceleration | rad/s² |

16.610 |

| Max. motor current | A |

12 |

| Thermal time constant (winding) | s | 20 |

| Nom. current poor thermal connection good thermal connection |

A A |

3 5 |

| Max. torque |

mNm |

750 |

| Torque constant |

mNm/A |

62,5 |

| Speed constant |

min-1/V |

126 |

| Terminal resistance |

mΩ |

585 |

| Terminal inductance |

μH |

300 |

| Electrical time constant |

ms | 0,512 |

| Number of pole pairs |

- | 7 |

| Rotor inertia |

g * cm² | 455 |

Do you have further questions, need information or support?

You can find more information in our "Frequently Asked Questions" section or by talking to our experts.